Milestone clean chemistry systems for atomic spectroscopy

During trace and ultra-trace elemental analysis a number of external factors (such as reagent purity, cross contamination, etc.) can critically impact the quality of the results. The inability to control the analytical blank (its chemical composition, its measurement, its effective control) is often the primary source of error and the limiting factor for trace analysis. Milestone has developed an innovative and complete line of systems and accessories for control and reduction of the analytical blank in ICP-MS, ICP-AES and GFAA. These instruments are dedicated to acid purification, ultratrace cleaning of vessels and reduction of contamination from vessel surfaces.

Acid distillation systems – make your own ultrapure acids

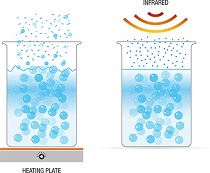

Chemical reagents used during analysis are an important source of the analytical blank. Sub-boiling distillation has been demonstrated to be the best method of acid purification and offers an optimal purification method for preparation of high purity reagents. The systems use contactless infrared lamps to vapourise the surface liquid just below the boiling point whereas conventional distillation systems use a strong boiling action that can result in contamination of the original liquid with the distillate. The gentle surface evaporation during sub-boiling distillation prevents the formation of spray or droplets and therefore produces high purity acid.

Chemical reagents used during analysis are an important source of the analytical blank. Sub-boiling distillation has been demonstrated to be the best method of acid purification and offers an optimal purification method for preparation of high purity reagents. The systems use contactless infrared lamps to vapourise the surface liquid just below the boiling point whereas conventional distillation systems use a strong boiling action that can result in contamination of the original liquid with the distillate. The gentle surface evaporation during sub-boiling distillation prevents the formation of spray or droplets and therefore produces high purity acid.

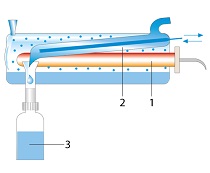

The subPUR and duoPUR have single and double quartz distillation units with infrared heating elements (1), a water cooled condenser (2), and a high-purity PFA collection bottle (3). The vapourised acid is collected on the inclined water-cooled condenser and drips into the collection bottle. The distillation process is microprocessor controlled, allowing the user to set the distillation time and power level by using a compact control terminal with easy-to-read, bright, full-colour, touch-screen display. The distillation rate ranges from 50 to 400 ml per hour, depending on the power setting and the temperature of the cooling water.

The subPUR and duoPUR have single and double quartz distillation units with infrared heating elements (1), a water cooled condenser (2), and a high-purity PFA collection bottle (3). The vapourised acid is collected on the inclined water-cooled condenser and drips into the collection bottle. The distillation process is microprocessor controlled, allowing the user to set the distillation time and power level by using a compact control terminal with easy-to-read, bright, full-colour, touch-screen display. The distillation rate ranges from 50 to 400 ml per hour, depending on the power setting and the temperature of the cooling water.

The subCLEAN is a compact system that uses sub-boiling distillation with forced air cooling where all parts in contact with acid are made of high purity PTFE making it suitable for use with HF. Offering an optimal purification method for preparation of high purity reagents, the subCLEAN system is also suitable for purification of HNO3 and HCl.

The subCLEAN is a compact system that uses sub-boiling distillation with forced air cooling where all parts in contact with acid are made of high purity PTFE making it suitable for use with HF. Offering an optimal purification method for preparation of high purity reagents, the subCLEAN system is also suitable for purification of HNO3 and HCl.

All three sub-boiling distillation systems are available with an automatic filling and draining system. The pumping system reduces the operator exposure to acids during filling and draining.

Features

- Up to 90% cost saving of ultra-pure acids by purifying low cost reagent grade acids

- High productivity, up to 400ml per hour

- Continuous supply of fresh high purity acids

- “On-demand” acid purification

- Re-purification of contaminated acids

- Single or double distillation depending on requirements

Acid cleaning system

Cleaning various accessories used in trace analysis work is a critically important laboratory routine. Traditional cleaning methods require soaking items in hot acids, often for several hours. Furthermore, generally effective, large volumes of acid are consumed and need to be changed regularly. There is also the risk of exposure to hot acids and acid vapours.

Cleaning various accessories used in trace analysis work is a critically important laboratory routine. Traditional cleaning methods require soaking items in hot acids, often for several hours. Furthermore, generally effective, large volumes of acid are consumed and need to be changed regularly. There is also the risk of exposure to hot acids and acid vapours.

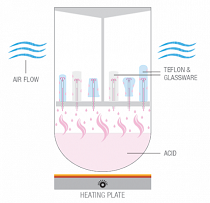

The TraceCLEAN is an automated, self-contained, acid steam cleaning system that thoroughly and safely cleans digestion vessels, inserts and AA, ICP, ICP-MS accessories. The automatic acid reflux system produces freshly distilled acids within the sealed unit and ensures thorough cleaning. Any trace metal contaminants that are present in the cleaning acid stay within the reservoir and do not come in contact with the cleaned trace accessories.

The TraceCLEAN is an automated, self-contained, acid steam cleaning system that thoroughly and safely cleans digestion vessels, inserts and AA, ICP, ICP-MS accessories. The automatic acid reflux system produces freshly distilled acids within the sealed unit and ensures thorough cleaning. Any trace metal contaminants that are present in the cleaning acid stay within the reservoir and do not come in contact with the cleaned trace accessories.

Steam cleaning with nitric or hydrochloric acid vapours is a very effective cleaning method for preconditioning and routine cleaning of containers and apparatus. The container to be cleaned is placed over a PTFE coated glass rod. Acid in the lower reservoir is heated, and purified acid vapour travels up through the glass rod and condenses on the container, removing surface contamination.

Features

- Perfect for unattended cleaning of all TFM, PFA, glass, and quartz ultra-trace accessories, including microwave digestion vessels and ICP/ICP-MS accessories (torches, etc.)

- Only ultra-pure, acid vapours come in contact with the surface of the items to be cleaned

- Clean components do not remain in contact with the cleaning acids after the surface contamination is removed

- Items are cooled inside the TraceCLEAN assuring no airborne contamination

- Built-in exhaust/cooling reduces operator’s exposure to acid vapours

- Teflon racks and holders minimize handling of freshly cleaned items

- Automatic temperature control

- PTFE-coated stainless steel compartment assures system durability and prevents use-to-use contamination

THINK BLANK – Clean chemistry tools for atomic spectroscopy

Instrumental analysis has continuously evolved in the last decade and determination of trace elements is becoming a routine task in analytical laboratories. A laboratory must have full control of analytical blanks and sample preparation for obtaining accurate results. The application of instruments and strategies to control sample prep blank is often called a “Clean Chemistry” technique.

Instrumental analysis has continuously evolved in the last decade and determination of trace elements is becoming a routine task in analytical laboratories. A laboratory must have full control of analytical blanks and sample preparation for obtaining accurate results. The application of instruments and strategies to control sample prep blank is often called a “Clean Chemistry” technique.

The THINK BLANK book discusses how to control contaminations and modern strategies for microwave assisted sample preparation. Topics include microwave digestion, evaporation, use of inserts for low sample amounts, and single vessel considerations