Single-step cleavage and deprotection system

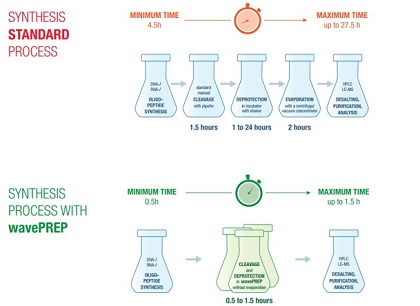

During oligonucleotide production, the final stage in synthesis involves cleavage from the solid support and the removal of the protecting groups. Although the synthesis process is automated, the post-processing stages that involve cleavage and deprotection are still carried out manually. This approach creates a bottleneck in the production workflow affecting productivity and efficiency.

To address this task, Milestone has developed wavePREP, an automated efficient, rapid, and safe tool for the post-processing step in oligonucleotide production. The process combines cleavage, deprotection, and evaporation into a single step ensuring both a superior workflow and product yields.

Features

- Deep well plates and column are not in contact with the liquid reagent so oligos remain dry during the entire process

- Operate with deep well plates or column with up to 6 deep well plates processed simultaneously

- Good quality of oligonucleotides with excellent deprotection yield in 90 minutes

- High productivity & easy handling with a single method

- No need for evaporation phase after cleavage and deprotection process

- Increased safety with no exposure to chemicals plus less smell of ammonia in the laboratory

Cleavage and deprotection steps

The manual steps of cleavage and deprotection have a direct impact on the oligonucleotide final yield, productivity, and laboratory workflow, due to the fact that their completion takes several hours. These stages are usually carried out by immersing the plates into ammonia solutions or other reagents, thus requiring an evaporation step and creating unpleasant laboratory conditions.

The manual steps of cleavage and deprotection have a direct impact on the oligonucleotide final yield, productivity, and laboratory workflow, due to the fact that their completion takes several hours. These stages are usually carried out by immersing the plates into ammonia solutions or other reagents, thus requiring an evaporation step and creating unpleasant laboratory conditions.

The system offers a new approach to the process by providing cleavage and deprotection of oligonucleotides in a single step plus evaporation in only 90 minutes, saving up to 95% of the traditional processing time. Reaction conditions are accurately controlled to ensure complete process control and to maximise the yield. Once the procedure has finished, oligonucleotides can be directly desalted, for example with acetonitrile, and eluted from the solid support with the appropriate buffer solution without further steps.

Workflow

The process begins by placing the deepwell plates or columns into the dedicated holder that is lowered into the wavePREP reactor. Once the reactor is sealed, the software-controlled pump automatically loads the required reagent volume. By using a dedicated pumping system avoids the operator’s exposure to chemicals. Subsequently the microwave heating program starts and the gas phase is generated where the accurate temperature and pressure control ensures high safety and reliability of the complete process.

The process begins by placing the deepwell plates or columns into the dedicated holder that is lowered into the wavePREP reactor. Once the reactor is sealed, the software-controlled pump automatically loads the required reagent volume. By using a dedicated pumping system avoids the operator’s exposure to chemicals. Subsequently the microwave heating program starts and the gas phase is generated where the accurate temperature and pressure control ensures high safety and reliability of the complete process.

At the completion of the heating procedure, a water-chiller provides fast cooling, followed by the automated venting and opening of the chamber. The deepwell plates or columns are now ready for elution without the need of the evaporation step.

Holders are available for different supports, such as deepwell plates, columns, or glass containers to match any requirement. The flexible configurations and large reactor enable processing of up to 6 deepwell plates in only 90 minutes, becoming an ideal solution for small to large-scale processes.

Safety

WavePREP has an intrinsic operation safety thanks to the ruggedness of the stainless-steel reactor and the highest manufacturing standards. The reactions take place inside the sealed stainless steel reactor with liner that safely handles the pressure during the process.

WavePREP has an intrinsic operation safety thanks to the ruggedness of the stainless-steel reactor and the highest manufacturing standards. The reactions take place inside the sealed stainless steel reactor with liner that safely handles the pressure during the process.

The workflow of the system with the automated pump removes the handling of chemicals and any potential operator exposure whilst ensuring a fully controlled process through the temperature and pressure sensors.

User interface

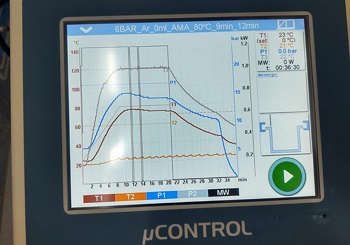

Oligonucleotide synthesis yield strongly depends on the cleavage and deprotection processes, the wavePREP accurate temperature and pressure sensors ensure optimum control of the reaction procedure for a maximised yield.

Oligonucleotide synthesis yield strongly depends on the cleavage and deprotection processes, the wavePREP accurate temperature and pressure sensors ensure optimum control of the reaction procedure for a maximised yield.

All the reaction parameters and other functionalities are fully controlled and tracked by the user interface in full compliance with GMP regulations. Parameters controlled include the temperature of the gas phase, temperature of the cooling jacket, temperature of the base load, and pressure of the vessel. Automated operation includes loading of reagent, purging of gases, and removal of reagents at the end of the process.