Milestone ultraWAVE3 microwave digestion system

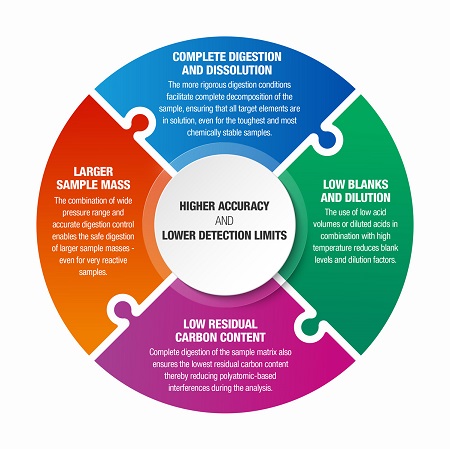

The ultraWAVE3 features Milestone’s patented single chamber reaction (SRC) technology in a fully automated benchtop package. Through advanced design and engineering, Milestone has been able to reduce the size of SRC technology, resulting in a small benchtop unit that can fit in even the smallest lab. The ultraWAVE3 can digest up to 40 samples – of any matrix – simultaneously. With SRC, all samples are in the same vessel so any combination of sample types with different acid chemistries can be digested at the same time and there is no need to batch samples of the same type into separate runs. Simply weigh the sample into a vial, add acid and place into the sample rack. The ultraWAVE3 is perfect for laboratories that have multiple sample types to digest, or simply want the convenience of SRC technology. The superior digestion quality and minimal blank contribution of SRC makes the system an ideal complement to ICP-MS and AA

The ultraWAVE3 includes several technology advances to current SRC technology that further enhances the well-proven benefits of this technique. New features in the technology enable laboratories to experience higher performance, greater productivity, and more streamlined workflow, providing them with improved competitiveness and a lower cost of ownership. Several aspects of the system, such as reduced handling and cleaning and the ability to process any samples simultaneously, streamline the daily routine of the lab, reducing turnaround time and increasing lab efficiency.

The ultraWAVE3 includes several technology advances to current SRC technology that further enhances the well-proven benefits of this technique. New features in the technology enable laboratories to experience higher performance, greater productivity, and more streamlined workflow, providing them with improved competitiveness and a lower cost of ownership. Several aspects of the system, such as reduced handling and cleaning and the ability to process any samples simultaneously, streamline the daily routine of the lab, reducing turnaround time and increasing lab efficiency.

Principles of operation

At the heart of ultraWAVE3 is the Single Reaction Chamber (SRC), a stainless-steel reactor with a high-purity PTFE-TFM liner and cover that serves as both microwave cavity and digestion vessel. Samples and reagents are placed in vials and racks, lowered into the liner containing a water-based solution and then the reactor is closed. The water-based load maintains the temperature regardless of the sample and acid mixtures in the vials. After the chamber is closed it is pre-pressurised with inert gas to prevent boiling of the reagents, loss of elements, and sample cross-contamination. Microwave heating starts and the digestion cycle is continuously controlled in all vials using an advanced contactless temperature sensor.

At the heart of ultraWAVE3 is the Single Reaction Chamber (SRC), a stainless-steel reactor with a high-purity PTFE-TFM liner and cover that serves as both microwave cavity and digestion vessel. Samples and reagents are placed in vials and racks, lowered into the liner containing a water-based solution and then the reactor is closed. The water-based load maintains the temperature regardless of the sample and acid mixtures in the vials. After the chamber is closed it is pre-pressurised with inert gas to prevent boiling of the reagents, loss of elements, and sample cross-contamination. Microwave heating starts and the digestion cycle is continuously controlled in all vials using an advanced contactless temperature sensor.

An integrated water-cooling circuit maintains the stainless steel chamber at a reduced temperature. At the end of the heating cycle, the cooling circuit promotes rapid cooling of the digestion vials that is followed by automatic venting of the chamber. The reactor is then opened and the digested sample solutions are ready for dilution and analysis.

Features

- Any combination of sample type and weight with different acids in a single run with no method development

- High pressure and temperature reactor up to 199 bar and 300°C ensuring complete digestion

- Acid-resistant stainless steel construction enables use of HCl in all racks, no need of special vials/caps or additional preparation stages

- Less acid used per sample (typical 2 – 4ml) and higher sample weights (up to 1.5g)

- Available with racks of 7, 20, 27 and 40 vials per batch without any need for capping or uncapping

- Standard laboratory sample tubes can be used such as ICP autosampler vials.

- Identical temperature and pressure conditions for all samples with no cross-contamination

- True contactless temperature sensor to directly control the digestion of all samples

- Automatic opening/closing of the pressure vessel with built in exhaust of acid vapours

- Noiseless water-cooled magnetron ensures higher heating efficiency along with quieter working conditions

- Disposable vessel option eliminates cleaning stage

- Advanced integrated terminal with user friendly software and full GLP documentation

Simplified handling

The vials and racks of ultraWAVE3 are specifically designed to reduce assembly and disassembly time. The operator has only to place loose-fitting caps on the vials and the rack is ready for the digestion process.

The vials and racks of ultraWAVE3 are specifically designed to reduce assembly and disassembly time. The operator has only to place loose-fitting caps on the vials and the rack is ready for the digestion process.

This approach eliminates the operator time required for closing and opening of the vessels, typically involved with the rotor-based systems. The fast assembly of the vials coupled with the automatic closing and opening reduces the handling time significantly thereby reducing operating costs.

Digestion racks and vials

The wide selection of racks and vials enables the laboratory to match the detection limit, productivity, and application requirements. Racks are available with different capacities to fit any sample type and mass. Vials are available in high-purity TFM, high-purity quartz, and disposable glass. The vials are fitted with loose TFM caps to ensure pressure equalisation even when using HCl.

The wide selection of racks and vials enables the laboratory to match the detection limit, productivity, and application requirements. Racks are available with different capacities to fit any sample type and mass. Vials are available in high-purity TFM, high-purity quartz, and disposable glass. The vials are fitted with loose TFM caps to ensure pressure equalisation even when using HCl.

Avoid vessel cleaning and improve productivity

Rotor-based systems require digestion vessels with a complex construction to contain the elevated pressure within each vessel. Conversely, the SRC approach ensures equal pressures between the inside and outside of the vials, so vials can withstand elevated pressures using a much simpler construction. Thanks to this unique capability, the SRC technology even enables the use of inexpensive disposable glass tubes. This approach is commonly implemented for more routine applications and allows complete elimination of the tedious vessel cleaning step and concern for potential memory effects.

Rotor-based systems require digestion vessels with a complex construction to contain the elevated pressure within each vessel. Conversely, the SRC approach ensures equal pressures between the inside and outside of the vials, so vials can withstand elevated pressures using a much simpler construction. Thanks to this unique capability, the SRC technology even enables the use of inexpensive disposable glass tubes. This approach is commonly implemented for more routine applications and allows complete elimination of the tedious vessel cleaning step and concern for potential memory effects.

The ultraWAVE3 reduces hands-on operator time by up to 50%. Several steps are completed automatically by the system, such as the closing and venting of the chamber and automatic sealing of the vials. This reduces the operator time, increases the productivity, and ensures the safety of operation.

User interface

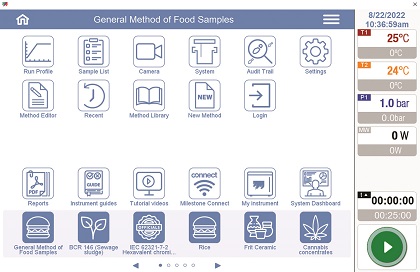

The ultraWAVE3 user interface provides fast and easy operation. For instance, with a routine digestion, beginning the process only requires few seconds, open the method and press “start”. SRC technology enables the use of a single method for the majority of sample types encountered in a typical laboratory. All the digestion parameters are automatically controlled by the system through a PID algorithm and are displayed on the terminal as well as listed on the side bar present in all pages.

The ultraWAVE3 user interface provides fast and easy operation. For instance, with a routine digestion, beginning the process only requires few seconds, open the method and press “start”. SRC technology enables the use of a single method for the majority of sample types encountered in a typical laboratory. All the digestion parameters are automatically controlled by the system through a PID algorithm and are displayed on the terminal as well as listed on the side bar present in all pages.

The system includes a comprehensive list of methods including official and standard methods that guide the operator in the optimisation of parameters. The time for any method development is therefore greatly reduced. Customised methods can also be created and stored on the system.

In addition the terminal can display tutorial videos, instrument guides, and part numbers for consumables if required.

Low cost of ownership

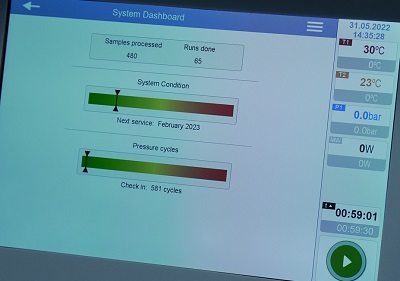

An important consideration in investment of instrumentation includes the costs involved with maintenance as well as operation.

An important consideration in investment of instrumentation includes the costs involved with maintenance as well as operation.

The ultraWAVE3 SRC technology introduces a completely new approach to sample preparation that impacts both of these cost areas. The consumables costs have been significantly reduced, moving from complex and expensive digestion vessels to simple and less expensive vials or even disposable glass tubes.

A usage-based preventive maintenance program minimise laboratory costs. The number of runs is monitored along with the number of samples processed, and the system indicates the time for the next service or system check.

Milestone Connect

Included with the ultraWAVE3 is a unique web based application – Milestone Connect. The app provides up to date information and extended instrument monitoring of the digestion run from outside the laboratory. The app works on various external devices such as PC, tablets or smartphones.

Included with the ultraWAVE3 is a unique web based application – Milestone Connect. The app provides up to date information and extended instrument monitoring of the digestion run from outside the laboratory. The app works on various external devices such as PC, tablets or smartphones.

The integral database includes specific and detailed information on the installed equipment (list of parts, technical notes, user manual, video tutorials, etc), continuously updated application notes, a library of available scientific articles published in scientific magazines, and a help-on-line section that provides instant support available 24 hours a day, 7 days a week.