The traditional extraction methods for the determination of fats in foods are well documented, especially for the dairy industry. They involve either acid or alkaline hydrolysis and then solvent extraction. These methods are labour intensive, require long extraction times, and have a high solvent consumption. Alternative gravimetric processes that are able to reduce the working steps and costs of these methods are therefore becoming more popular.

The traditional extraction methods for the determination of fats in foods are well documented, especially for the dairy industry. They involve either acid or alkaline hydrolysis and then solvent extraction. These methods are labour intensive, require long extraction times, and have a high solvent consumption. Alternative gravimetric processes that are able to reduce the working steps and costs of these methods are therefore becoming more popular.

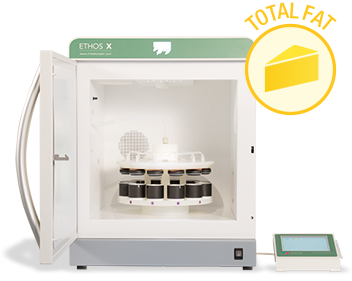

One such process uses a Milestone EthosX microwave enhanced extraction system that provides faster, safer and lower-cost fat extraction than traditional methods whilst providing equivalent results. The acid hydrolysis and solvent extraction stages work in parallel at elevated temperature and pressure conditions. This reduces both the working time as well as costs related to the large amounts of solvent used in traditional methods.

The Milestone EthosX system can be used with many food matrices and accurate total fat determination of 12 samples can be achieved in just 90 minutes using 25ml of solvent. This would typically take 180 minutes and 100ml of solvent with traditional methods.

Aside from the speed, safety and efficiency, advantages of the EthosX include its large sample size of up to 10 grams and the fat obtained can also be used for fatty acid analysis by GC or GCMS. The Milestone EthosX is controlled via a full-colour, user-friendly touchscreen interface with full data storage.

Request further information