synthWAVE microwave synthesis system

The new synthWAVE features Milestone’s patented single chamber reaction (SRC) technology in a fully automated benchtop system that expands current capabilities of microwave synthesis systems.

The synthWAVE matches the growing demand for scale up of chemical reactions from grams to kilogram and handles single or multiple reactions at temperatures up to 300°C and pressures to 199 bar. These enhanced operating conditions allow the chemist to run large-scale batch and parallel reactions not previously possible in a microwave system.

Features

- High pressure capability allows for use of a wider range of low-boiling reagents, reactants, and solvents

- Reactions in inert atmosphere or reactant gases such as hydrogen or oxygen

- Software controlled stirring in all vessels from 22 vial system to single 1L PTFE vessel

- Easy sampling enables monitoring of products during reaction

- Range of racks including 4, 5, 15, and 22 positions with no vessel assembly required

- Range of vial types including disposable glass, quartz, and PTFE all with PTFE caps

- Water cooled microwave cavity that greatly reduces cooling time whilst increasing productivity

Racks and vials

Reactions can be carried out directly in the 1L PTFE vessel or in multiple vials. Vials are available in disposable glass, quartz, and PTFE, each with loose fitting PTFE caps to ensure equal pressure for each reaction. Racks are available in a number of configurations including 4, 5, 15, and 22 positions with each tray numbered for easy identification of vial number. The sample racks fit easily onto a balance so reagents can be weighed directly into vials. No vessel assembly or disassembly is required pre- or post-reaction making easy sample handling.

Reactions can be carried out directly in the 1L PTFE vessel or in multiple vials. Vials are available in disposable glass, quartz, and PTFE, each with loose fitting PTFE caps to ensure equal pressure for each reaction. Racks are available in a number of configurations including 4, 5, 15, and 22 positions with each tray numbered for easy identification of vial number. The sample racks fit easily onto a balance so reagents can be weighed directly into vials. No vessel assembly or disassembly is required pre- or post-reaction making easy sample handling.

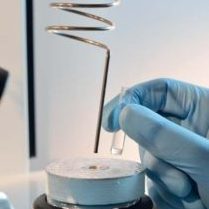

Easy sampling and stirring

Monitoring of a reaction is easy with the integral sample reaction tube that allows products to be analysed at any time during the reaction.

Monitoring of a reaction is easy with the integral sample reaction tube that allows products to be analysed at any time during the reaction.

The synthWAVE includes a software controlled powerful stirrer that ensures continuous stirring in the 1L PTFE vessel or in all vials whenever a rack is being used. This ensures consistent and reliable results from batch to batch.

Benefits

- Fast screening with simultaneous reactions using different solvents, catalysts, and reaction conditions

- Scale directly up from ul to working in the litre vessel

- Reactions completed in minutes compared to hours with current techniques

- Enhanced selectivity and improved yields

- Lower by-products formation and sample contamination

- Reduced quantities of chemicals used

- Reduced energy consumption for the laboratory

Applications

| Oxidations & reductions | High pressure hydrogenation | Polymerisation |

| Esterification & Ammidation | Cycloadditions | Nanoparticle preparation |

| Gas insertion | Coating | Click chemistry |

| Dechlorination | Multicomponent reactions | Modification of carbon nanotubes |

| Stereoselective transformations | Reagents & materials | Desulphuration |

User Interface

The SynthWAVE is operated via a control terminal featuring a full-colour 6.5″ touch screen display that enables simple and intuitive, but extremely flexible and powerful control over the reaction process. Method setup only requires a set target temperature, ramp time and hold time. The system automatically follows the desired temperature profile, continuously varying the microwave output via a sophisticated Proportional Integral Derivative (PID) controller, regardless of reagent volume or number of vials in the run. EasyCONTROL software features full audit trail capability plus multi-level user access security: each operator has a personal password to access the software. Run data are stored on a flash drive or USB memory stick and can be transferred to a PC with the optional EasyDOC software. The software also controls a powerful stirrer that ensures vigorous stirring in the 1L PTFE vessel, or in all vials whenever a rack is used, thus assuring reliable and consistent results.

The SynthWAVE is operated via a control terminal featuring a full-colour 6.5″ touch screen display that enables simple and intuitive, but extremely flexible and powerful control over the reaction process. Method setup only requires a set target temperature, ramp time and hold time. The system automatically follows the desired temperature profile, continuously varying the microwave output via a sophisticated Proportional Integral Derivative (PID) controller, regardless of reagent volume or number of vials in the run. EasyCONTROL software features full audit trail capability plus multi-level user access security: each operator has a personal password to access the software. Run data are stored on a flash drive or USB memory stick and can be transferred to a PC with the optional EasyDOC software. The software also controls a powerful stirrer that ensures vigorous stirring in the 1L PTFE vessel, or in all vials whenever a rack is used, thus assuring reliable and consistent results.

References

Wu, Z., Boretto, E., Medlock, J., Bonrath, W., Cravotto, G.

Effects of ultrasound and microwave on selective reduction: Catalyst preparation and reactions

ChemCatChem, 2014, 6, 2762-2783

Calcio Gaudino, E., Carnaroglio, D., Martina, K., Palmisano, G., Penoni, A., Crovotto, G.

Highly efficient microwave -assisted CO aminocarbonylation with a recyclable Pd(II)/TPP-β-cyclodextrin cross – linked catalyst

Org. Process Res. Dev., 2015, DOI: 10.1021/op5003374

Calcio Gaudino, E., Tagliapietra, S., Martina, K., Barge, A., Lolli, M., Terreno, E., Lembo, D., Cravotto, G.

A novel SWCNT platform bearing DOTA and β – cyclodextrin units. “One shot” multidecoration under microwave irradiation

Org. Biomol. Chem., 2014, 12, 4708

Wu, Z., Cherkasov, N., Cravotto, G., Borretto, E., Ibhadon, A. O., Medlock, J., Bonrath, W.

Ultrasound – and microwave – assisted preparation of lead – free palladium catalyst: Effects on the kinetics of diphenylacetylene semi – hydrogenation

ChemCatChem, 2015, DOI: 10.1002/cctc.201402999

Tabasso, S., Montoneri, E., Carnaroglio, D., Caporaso, M., Cravotto, G.

Microwave – assisted flash conversion of non – edible polysaccharides and post – harvest tomato plant waste to levulinic acid

Green Chem., 2014, 16, 73

Cravotto, G., Calcio Gaudino, E., Tagliapietra, S., Carnaroglio, D., Procopio, A.

A green approach to heterogeneous catalysis using ligand-free, metal-loaded cross – linked cyclodextrins

Green Process Synth, 2012, 1, 269–273

Carnaroglio, D., Tabasso, S., Kwasek, B., Bogdal, D., Calcio Gaudino, E., Cravotto, G.

From lignocellulosic biomass to lactic – and glycolic – acid oligomers: a gram – scale microwave – assisted protocol

ChemSusChem, 2015, DOI: 10.1002/cssc.201403183

Caporaso, M., Cravotto, G., Georgakopoulos, S., Heropoulos, G., Martina, K., Tagliapietra, S.

Pd/C-catalyzed aerobic oxidative esterification of alcohols and aldehydes: a highly efficient microwave – assisted green protocol

Beilstein J. Org. Chem., 2014, 10, 1454–1461